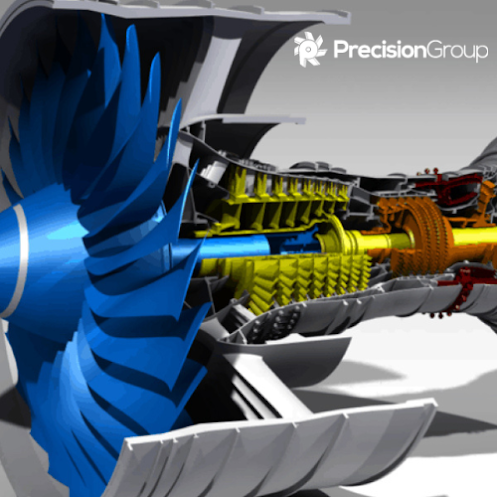

Revealing the Fine Art of Making Plastic Injection Molds

Precision is crucial in the fast-paced world of production, and the creation of plastic injection molds is one procedure that stands out for its efficiency and accuracy. This complex art form is essential to the manufacturing of many plastic products, ranging from common consumer goods to complex components for electronic equipment. To grasp the importance of plastic injection mold production and the painstaking procedure that goes into it, let's explore this interesting field.

The Basis: Comprehending Injection Molding

The injection molding process is the foundation of the production of plastic injection molds. This extensively used production technique is pouring melted plastic resin into a mold hole. The ultimate form of the product is determined by the precisely made mold. This procedure makes it possible to produce.

The Artistry: Creating the Mold

Designing the mold is the first step in producing a faultless plastic product. Together, engineers and designers create a mold that takes into consideration material flow, cooling, and shrinkage in addition to accurately replicating the intended product. This careful planning guarantees that the final product satisfies the necessary requirements in terms of quality and specs.

Materials Are Important: Selecting the Proper Resin

A crucial step in the production of plastic injection molds is choosing the right plastic resin. Certain qualities, like flexibility, durability, or heat resistance, are needed for diverse applications. In order to select the best resin for each unique mold, manufacturers carefully consider these specifications, making sure that the finished product has the needed qualities.

Machining with precision: Making the Mold

The actual mold-making process begins after the design is complete and the materials are selected. To create the mold with unmatched accuracy, precision machining techniques like CNC milling and EDM (Electrical Discharge Machining) are used. A great degree of skill and attention to detail are required for this step because even small flaws can have an impact on the final product's quality.

Using Injection Molding to Bring Designs to Reality

The injection molding machine takes center stage now that the mold is ready. After being heated and injected into the mold, the plastic resin is let to cool and harden. Until the desired number of items is produced, this process is repeated. Automation has increased productivity even more, guaranteeing a quick and reliable manufacturing process.

Quality Assurance: Guaranteeing Excellence

The last injection cycle does not mark the end of the process of making a plastic injection mold. Strict quality control procedures are used to ensure that every product satisfies the required standards. This calls for a careful examination of the structural integrity, surface polish, and measurements. Any deviations are found and fixed to guarantee a perfect final result.

Conclusion:

The production of plastic injection mold design is unquestionably an artistic endeavor that combines dexterity, innovation, and artistry. Every stage, from the first design phase to the last quality check, necessitates a meticulous attention to detail and a dedication to excellence. The plastic injection mold manufacturing industry continues to be at the forefront of providing innovation and dependability to numerous sectors globally, despite ongoing breakthroughs in materials and technology.

.jpg)

Comments

Post a Comment